Page 289 - Reciprocating Compressors Operation Maintenance

P. 289

274 Reciprocating Compressors: Operation and Maintenance

Side Clearances

The side clearances of piston rings are checked by installing the rings in

their grooves on the piston. They should then be rolled around completely

to make sure there is no obstruction in the bottom of the ring groove at any

point, and side clearance should be checked with a feeler gauge.

The ring grooves must be in good condition, that is, not worn or

tapered, if poor sealing or breakage of the rings are to be avoided. Worn

ring grooves must be reconditioned.

Piston Ring Installation

Care should be taken when expanding rings over the piston. To pre-

vent permanent deformation or breakage, they should be spread no fur-

ther than necessary to clear the outside diameter of the piston.

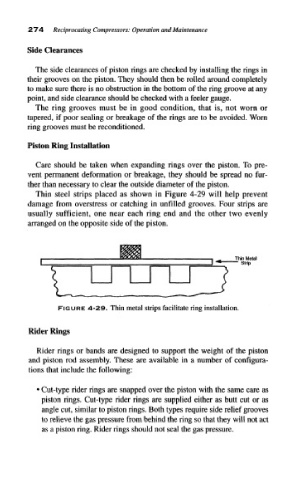

Thin steel strips placed as shown in Figure 4-29 will help prevent

damage from overstress or catching in unfilled grooves. Four strips are

usually sufficient, one near each ring end and the other two evenly

arranged on the opposite side of the piston.

FIGURE 4-29. Thin metal strips facilitate ring installation.

Rider Rings

Rider rings or bands are designed to support the weight of the piston

and piston rod assembly. These are available in a number of configura-

tions that include the following:

• Cut-type rider rings are snapped over the piston with the same care as

piston rings. Cut-type rider rings are supplied either as butt cut or as

angle cut, similar to piston rings. Both types require side relief grooves

to relieve the gas pressure from behind the ring so that they will not act

as a piston ring. Rider rings should not seal the gas pressure.