Page 294 - Reciprocating Compressors Operation Maintenance

P. 294

Overhaul and Repair of Reciprocating Compressors 279

A B C

Failure

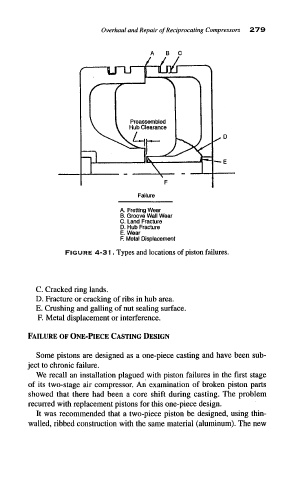

A. Fretting Wear

B. Groove Wall Wear

C. Land Fracture

D. Hub Fracture

E. Wear

F. Metal Displacement

FIGURE 4-3 i . Types and locations of piston failures.

C. Cracked ring lands.

D. Fracture or cracking of ribs in hub area.

E. Crushing and galling of nut sealing surface.

F. Metal displacement or interference.

FAILURE OF ONE-PIECE CASTING DESIGN

Some pistons are designed as a one-piece casting and have been sub-

ject to chronic failure.

We recall an installation plagued with piston failures in the first stage

of its two-stage air compressor. An examination of broken piston parts

showed that there had been a core shift during casting. The problem

recurred with replacement pistons for this one-piece design.

It was recommended that a two-piece piston be designed, using thin-

walled, ribbed construction with the same material (aluminum). The new