Page 298 - Reciprocating Compressors Operation Maintenance

P. 298

Overhaul and Repair of Reciprocating Compressors 283

REAPPLICATION OF BABBITT-SPRAYED RIDER BANDS

The following procedures should be followed when reapplying bab-

bitt-sprayed rider bands.

Surface Preparation and Spraying

1. Clean all old babbitt from the rider ring grooves by machining to

base metal. Take extreme care at this point to assure that all babbitt

is removed, while keeping the depth of the groove to a minimum. If

machining is not necessary, sandblast the rider groove to bare metal

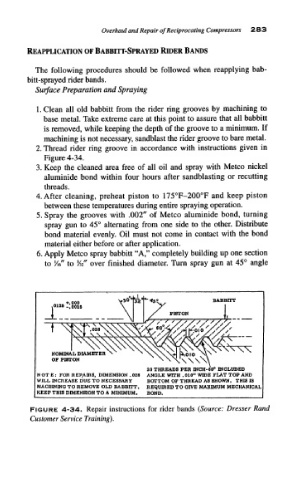

2. Thread rider ring groove in accordance with instructions given in

Figure 4-34.

3. Keep the cleaned area free of all oil and spray with Metco nickel

aluminide bond within four hours after sandblasting or recutting

threads.

4. After cleaning, preheat piston to 175°F-2QO°F and keep piston

between these temperatures during entire spraying operation.

5. Spray the grooves with .002" of Metco aluminide bond, turning

spray gun to 45° alternating from one side to the other. Distribute

bond material evenly. Oil must not come in contact with the bond

material either before or after application.

6. Apply Metco spray babbitt "A," completely building up one section

to y\" to Yn' over finished diameter. Turn spray gun at 45° angle

BABBITT

.0128 _

NOMINAL DIAMETER

OF PISTON

20 THREADS PER INCH-60 0 INCLUDED

NOTE: FOR REPAIRS, DIMENSION .028 ANGLE WITH .010" WIDE FLAT TOP AND

WILL OTCREASE DUE TO NECESSARY BOTTOM OF THREAD AS SHOWN. THIS 18

MACHINING TO REMOVE OLD BABBITT. REQUIRED TO GIVE MAXIMUM MECHANICAL

KEEP THIS DIMENSION TO A MINIMUM. BOND.

FIGURE 4-34. Repair instructions for rider bands (Source: Dresser Rand

Customer Service Training).