Page 299 - Reciprocating Compressors Operation Maintenance

P. 299

284 Reciprocating Compressors: Operation and Maintenance

alternately from one side to the other until threads are filled, and

then at 90° until completely built up,

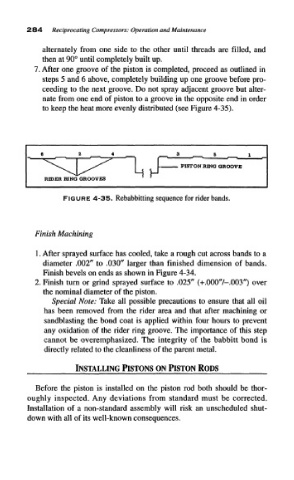

7, After one groove of the piston is completed, proceed as outlined in

steps 5 and 6 above, completely building up one groove before pro-

ceeding to the next groove. Do not spray adjacent groove but alter-

nate from one end of piston to a groove in the opposite end in order

to keep the heat more evenly distributed (see Figure 4-35).

PISTON BENO GROOVE

H H

RIDER RING GROOVES

FIGURE 4-35. Rebabbitting sequence for rider bands.

Finish Machining

1. After sprayed surface has cooled, take a rough cut across bands to a

diameter .002" to .030" larger than finished dimension of bands.

Finish bevels on ends as shown in Figure 4-34.

2. Finish turn or grind sprayed surface to .025" (+.0007-.003") over

the nominal diameter of the piston.

Special Note: Take all possible precautions to ensure that all oil

has been removed from the rider area and that after machining or

sandblasting the bond coat is applied within four hours to prevent

any oxidation of the rider ring groove. The importance of this step

cannot be overemphasized. The integrity of the babbitt bond is

directly related to the cleanliness of the parent metal.

Before the piston is installed on the piston rod both should be thor-

oughly inspected. Any deviations from standard must be corrected.

Installation of a non-standard assembly will risk an unscheduled shut-

down with all of its well-known consequences.