Page 292 - Reciprocating Compressors Operation Maintenance

P. 292

Overhaul and Repair of Reciprocating Compressors 2,77

4. Both counterbore or face of piston (piston rod shoulder, collar, or

piston nut end) must not be galled or rough. If not in good condi-

tion, rough or marked, machine to clean up.

5. Measure the inside diameter of piston boss. If this diameter is

greater than the normal diameter of the bore by .002", the piston

will not have the proper fit to the rod. Depending on the design of

the piston and the boss, a repair may be made by boring oversize

and installing a bushing. If the design is such that there is not

enough material to install a bushing, the piston rod must be built up

and ground to an amount equal to the oversize bore. Clearance

between piston bore ID and piston rod OD is .001" to .0025".

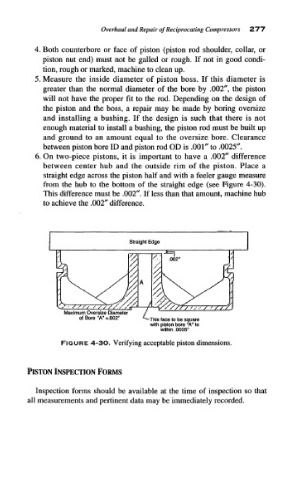

6. On two-piece pistons, it is important to have a .002" difference

between center hub and the outside rim of the piston. Place a

straight edge across the piston half and with a feeler gauge measure

from the hub to the bottom of the straight edge (see Figure 4-30).

This difference must be .002". If less than that amount, machine hub

to achieve the .002" difference.

Straight Edge

Maximum Oversize Diameter

of Bore "A" =.002" ^This face to be square

with piston bore "A" to

within .0005"

FIGURE 4-3O. Verifying acceptable piston dimensions.

PISTON INSPECTION FORMS

Inspection forms should be available at the time of inspection so that

all measurements and pertinent data may be immediately recorded.