Page 284 - Reciprocating Compressors Operation Maintenance

P. 284

Overhaul and Repair of Reciprocating Compressors 260

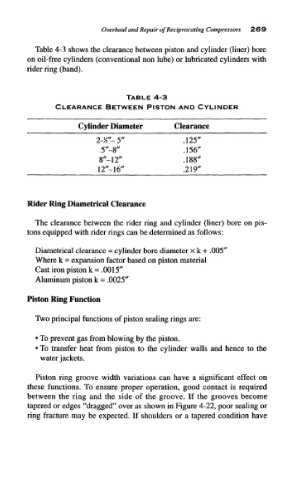

Table 4-3 shows the clearance between piston and cylinder (liner) bore

on oil-free cylinders (conventional non lube) or lubricated cylinders with

rider ring (band).

TABLE 4-3

CLEARANCE BETWEEN PISTON AND CYLINDER

Cylinder Diameter Clearance

2-M"-5" .125"

5"~8" .156"

8"~12" .188"

12"-16" .219"

Rider Ring Diametrical Clearance

The clearance between the rider ring and cylinder (liner) bore on pis-

tons equipped with rider rings can be determined as follows:

Diametrical clearance = cylinder bore diameter x k + .005"

Where k = expansion factor based on piston material

Cast iron piston k = .0015"

Aluminum piston k = .0025"

Piston Ring Function

Two principal functions of piston sealing rings are:

• To prevent gas from blowing by the piston.

• To transfer heat from piston to the cylinder walls and hence to the

water jackets.

Piston ring groove width variations can have a significant effect on

these functions. To ensure proper operation, good contact is required

between the ring and the side of the groove. If the grooves become

tapered or edges "dragged" over as shown in Figure 4-22, poor sealing or

ring fracture may be expected. If shoulders or a tapered condition have