Page 42 - Reciprocating Compressors Operation Maintenance

P. 42

Reciprocating Compressors and Their Applications 29

Discharge Volume of Compressed Air

yalve Suction Valve Compressed to

100 psi Discharged at t

100 psi

~^ P i P i > [z^pSB

r

WWrnrTl T

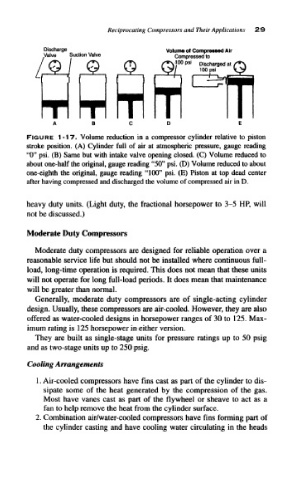

FIGURE 1-17. Volume reduction in a compressor cylinder relative to piston

stroke position. (A) Cylinder full of air at atmospheric pressure, gauge reading

"0" psi, (B) Same but with intake valve opening closed. (C) Volume reduced to

about one-half the original, gauge reading "50" psi. (D) Volume reduced to about

one-eighth the original, gauge reading "100" psi. (E) Piston at top dead center

after having compressed and discharged the volume of compressed air in D.

heavy duty units. (Light duty, the fractional horsepower to 3-5 HP, will

not be discussed.)

Moderate Duty Compressors

Moderate duty compressors are designed for reliable operation over a

reasonable service life but should not be installed where continuous full-

load, long-time operation is required. This does not mean that these units

will not operate for long full-load periods. It does mean that maintenance

will be greater than normal.

Generally, moderate duty compressors are of single-acting cylinder

design. Usually, these compressors are air-cooled. However, they are also

offered as water-cooled designs in horsepower ranges of 30 to 125. Max-

imum rating is 125 horsepower in either version.

They are built as single-stage units for pressure ratings up to 50 psig

and as two-stage units up to 250 psig.

Cooling Arrangements

1. Air-cooled compressors have fins cast as part of the cylinder to dis-

sipate some of the heat generated by the compression of the gas.

Most have vanes cast as part of the flywheel or sheave to act as a

fan to help remove the heat from the cylinder surface.

2. Combination air/water-cooled compressors have fins forming part of

the cylinder casting and have cooling water circulating in the heads