Page 46 - Reciprocating Compressors Operation Maintenance

P. 46

°;:^ 3 r— • - I T __ _ 3

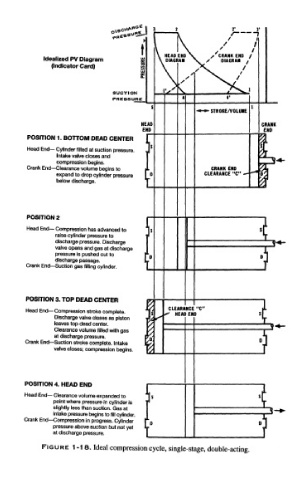

\ NEAD END \ /'CRANK ENO /

Idealized PV Diagram £ \ OlAGflA» X / DIAGRAM /

(Indicator Card) |>

\ >V / /

|AJ s\ ^k.

re \

\

Ck. X. /

'

1 's' \ /v^»

SUCTION

PRESSURE 4 4'

1

S

•«M»» STROKE/VOLUME

HEAD CRANK

END END

POSITION 1. BOTTOM DEAD CENTER I /A

sf

Head End— Cylinder filled at suction pressure. J

Intake valve closes and J

compression begins. j jj"*

Crank End— Clearance volume begins to JL CRANK ENO 3T

^*

expand to drop cylinder pressure I D CLEARANCE "C" — -* ^

f

below discharge. T

POSITION 2

Head End — Compression has advanced to s $f

raise cylinder pressure to I

discharge pressure. Discharge

valve opens and gas at discharge

pressure is pushed out to 0

discharge passage.

Crank End— Suction gas filling cylinder.

POSITION 3. TOP DEAD CENTER p i

CLEARANCE "C" 1

Head End — Compression stroke complete. \{ <* HEAD ENO Sj

Discharge valve closes as piston iL S* i

leaves top dead center. I/

T^

Clearance volume filled with gas ]// " " |""' J

at discharge pressure. pv

I

Crank End— Suction stroke complete. Intake t/ C J

valve closes; compression begins. T>

I

POSITION 4. HEAD END j I

Head End— Clearance volume expanded to ] s

point where pressure in cylinder is r '

slightly less than suction. Gas at I J

intake pressure begins to fill cylinder. 1 S^

Crank End — Compression in progress. Cylinder r 0

pressure above suction but not yet V J

at discharge pressure. [ ]

FIGURE 1-18. Ideal compression cycle, single-stage, double-acting.