Page 45 - Reciprocating Compressors Operation Maintenance

P. 45

32 Reciprocating Compressors: Operation and Maintenance

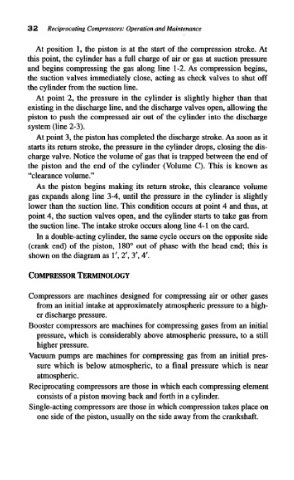

At position 1, the piston is at the start of the compression stroke. At

this point, the cylinder has a full charge of air or gas at suction pressure

and begins compressing the gas along line 1-2. As compression begins,

the suction valves immediately close, acting as check valves to shut off

the cylinder from the suction line.

At point 2, the pressure in the cylinder is slightly higher than that

existing in the discharge line, and the discharge valves open, allowing the

piston to push the compressed air out of the cylinder into the discharge

system (line 2-3).

At point 3, the piston has completed the discharge stroke. As soon as it

starts its return stroke, the pressure in the cylinder drops, closing the dis-

charge valve. Notice the volume of gas that is trapped between the end of

the piston and the end of the cylinder (Volume C). This is known as

"clearance volume."

As the piston begins making its return stroke, this clearance volume

gas expands along line 3-4, until the pressure in the cylinder is slightly

lower than the suction line. This condition occurs at point 4 and thus, at

point 4, the suction valves open, and the cylinder starts to take gas from

the suction line. The intake stroke occurs along line 4-1 on the card.

In a double-acting cylinder, the same cycle occurs on the opposite side

(crank end) of the piston, 180° out of phase with the head end; this is

shown on the diagram as 1', 2', 3', 4'.

COMPRESSOR TERMINOLOGY

Compressors are machines designed for compressing air or other gases

from an initial intake at approximately atmospheric pressure to a high-

er discharge pressure.

Booster compressors are machines for compressing gases from an initial

pressure, which is considerably above atmospheric pressure, to a still

higher pressure.

Vacuum pumps are machines for compressing gas from an initial pres-

sure which is below atmospheric, to a final pressure which is near

atmospheric.

Reciprocating compressors are those in which each compressing element

consists of a piston moving back and forth in a cylinder.

Single-acting compressors are those in which compression takes place on

one side of the piston, usually on the side away from the crankshaft.