Page 67 - Reciprocating Compressors Operation Maintenance

P. 67

54 Reciprocating Compressors: Operation and Maintenance

High-Pressure, Opposed Plunger, "Hyper Compressor" Running

Gear

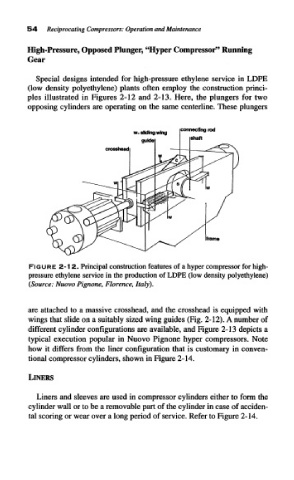

Special designs intended for high-pressure ethylene service in LDPE

(low density polyethylene) plants often employ the construction princi-

ples illustrated in Figures 2-12 and 2-13. Here, the plungers for two

opposing cylinders are operating on the same centerline. These plungers

w. adding wing

guide

crosshead

frame

FIGURE 2-12. Principal construction features of a hyper compressor for high-

pressure ethylene service in the production of LDPE (low density polyethylene)

(Source: Nuovo Pignone, Florence, Italy),

are attached to a massive crosshead, and the crosshead is equipped with

wings that slide on a suitably sized wing guides (Fig. 2-12). A number of

different cylinder configurations are available, and Figure 2-13 depicts a

typical execution popular in Nuovo Pignone hyper compressors. Note

how it differs from the liner configuration that is customary in conven-

tional compressor cylinders, shown in Figure 2-14.

LINERS

Liners and sleeves are used in compressor cylinders either to form the

cylinder wall or to be a removable part of the cylinder in case of acciden-

tal scoring or wear over a long period of service. Refer to Figure 2-14.