Page 81 - Reciprocating Compressors Operation Maintenance

P. 81

68 Reciprocating Compressors: Operation and Maintenance

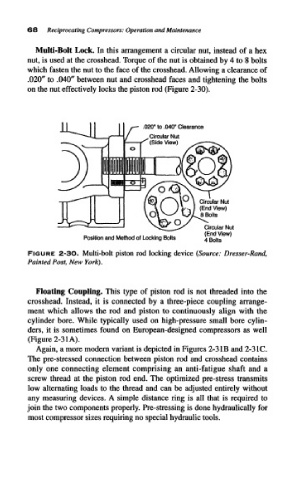

Multi-Bolt Lock. In this arrangement a circular nut, instead of a hex

nut, is used at the crosshead. Torque of the nut is obtained by 4 to 8 bolts

which fasten the nut to the face of the crosshead. Allowing a clearance of

.020" to .040" between nut and crosshead faces and tightening the bolts

on the nut effectively locks the piston rod (Figure 2-30).

.020" to .040" Clearance

Circular Nut

(End View)

Position and Method of Locking Bolts 4 Q 0 | ts

FIGURE 2-3O. Multi-bolt piston rod locking device (Source: Dresser-Rand,

Painted Post, New York).

Floating Coupling. This type of piston rod is not threaded into the

crosshead. Instead, it is connected by a three-piece coupling arrange-

ment which allows the rod and piston to continuously align with the

cylinder bore. While typically used on high-pressure small bore cylin-

ders, it is sometimes found on European-designed compressors as well

(Figure 2-31 A).

Again, a more modern variant is depicted in Figures 2-3IB and 2-31C.

The pre-stressed connection between piston rod and crosshead contains

only one connecting element comprising an anti-fatigue shaft and a

screw thread at the piston rod end. The optimized pre-stress transmits

low alternating loads to the thread and can be adjusted entirely without

any measuring devices. A simple distance ring is all that is required to

join the two components properly. Pre-stressing is done hydraulically for

most compressor sizes requiring no special hydraulic tools.