Page 85 - Reciprocating Compressors Operation Maintenance

P. 85

72 Reciprocating Compressors: Operation and Maintenance

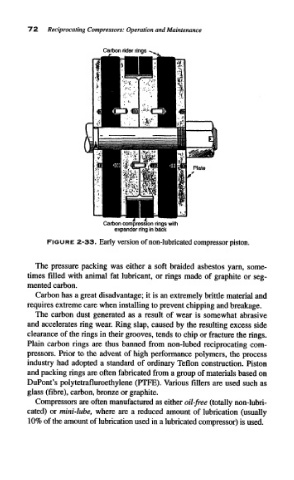

Carbon rider rings

Carbon compression rings with

expander ring in back

FIGURE 2-33. Early version of non-lubricated compressor piston.

The pressure packing was either a soft braided asbestos yarn, some-

times filled with animal fat lubricant, or rings made of graphite or seg-

mented carbon.

Carbon has a great disadvantage; it is an extremely brittle material and

requires extreme care when installing to prevent chipping and breakage.

The carbon dust generated as a result of wear is somewhat abrasive

and accelerates ring wear. Ring slap, caused by the resulting excess side

clearance of the rings in their grooves, tends to chip or fracture the rings.

Plain carbon rings are thus banned from non-lubed reciprocating com-

pressors. Prior to the advent of high performance polymers, the process

industry had adopted a standard of ordinary Teflon construction. Piston

and packing rings are often fabricated from a group of materials based on

DuPont's polytetrafluroethylene (PTFE). Various fillers are used such as

glass (fibre), carbon, bronze or graphite.

Compressors are often manufactured as either oil-free (totally non-lubri-

cated) or mini-lube, where are a reduced amount of lubrication (usually

10% of the amount of lubrication used in a lubricated compressor) is used.