Page 88 - Reciprocating Compressors Operation Maintenance

P. 88

Design and Mate rials for Reciprocating Compressor Components 7 5

The rider ring is either a solid or a split configuration; its size is deter-

mined by piston assembly weight only and is independent of operating

pressures.

CONVENTIONAL DESIGN FOR NON-LUBE SERVICE

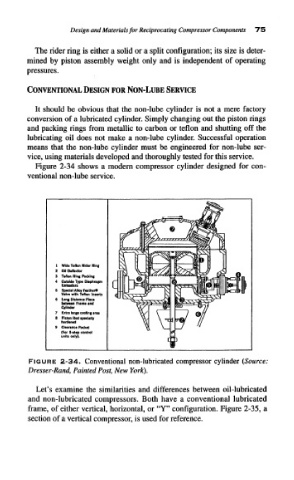

It should be obvious that the non-lube cylinder is not a mere factory

conversion of a lubricated cylinder. Simply changing out the piston rings

and packing rings from metallic to carbon or teflon and shutting off the

lubricating oil does not make a non-lube cylinder. Successful operation

means that the non-lube cylinder must be engineered for non-lube ser-

vice, using materials developed and thoroughly tested for this service.

Figure 2-34 shows a modern compressor cylinder designed for con-

ventional non-lube service.

4

Untotders

6 Special Alloy Fe»lher»

VMw with Teflon Inserts

6 Long Distance Piece

batmen Fnnra md

Cylinder

7 Erin Urge cooling area

8 Piiton Rod specially

fiardmtd

9 Clearance Pocket

(For 5 «tep control

unHi only).

FIGURE 2-34. Conventional non-lubricated compressor cylinder (Source:

Dresser-Rand, Painted Post, New York).

Let's examine the similarities and differences between oil-lubricated

and non-lubricated compressors. Both have a conventional lubricated

frame, of either vertical, horizontal, or "Y" configuration. Figure 2-35, a

section of a vertical compressor, is used for reference.