Page 92 - Reciprocating Compressors Operation Maintenance

P. 92

Design and Materials for Reciprocating Compressor Components 79

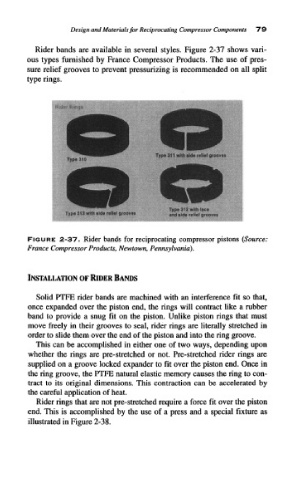

Rider bands are available in several styles. Figure 2-37 shows vari-

ous types furnished by France Compressor Products. The use of pres-

sure relief grooves to prevent pressurizing is recommended on all split

type rings.

FIGURE 2-37. Rider bands for reciprocating compressor pistons (Source:

France Compressor Products, Newtown, Pennsylvania).

INSTALLATION OF RIDER BANDS

Solid PTFE rider bands are machined with an interference fit so that,

once expanded over the piston end, the rings will contract like a rubber

band to provide a snug fit on the piston. Unlike piston rings that must

move freely in their grooves to seal, rider rings are literally stretched in

order to slide them over the end of the piston and into the ring groove.

This can be accomplished in either one of two ways, depending upon

whether the rings are pre-stretched or not. Pre-stretched rider rings are

supplied on a groove locked expander to fit over the piston end. Once in

the ring groove, the PTFE natural elastic memory causes the ring to con-

tract to its original dimensions. This contraction can be accelerated by

the careful application of heat.

Rider rings that are not pre-stretched require a force fit over the piston

end. This is accomplished by the use of a press and a special fixture as

illustrated in Figure 2-38.