Page 94 - Reciprocating Compressors Operation Maintenance

P. 94

Design and Materials for Reciprocating Compressor Components 81

FIGURE 2-39. Truncated piston for conventional non-lubricated compressor

pistons (Source: Joy Manufacturing Company, Division of Gardner-Denver,

Quincy, Illinois).

Piston Section

Rider Ring

'Piston Rings

Ring Carrier rlf c^iw| | I RWW l|-Piston

°

Rider Ring | SeCti n

Piston Section |JsW ""'^piston Rings

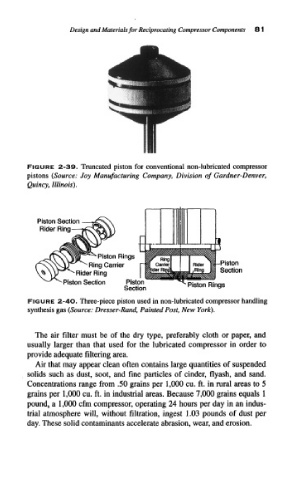

FIGURE 2-4O. Three-piece piston used in non-lubricated compressor handling

synthesis gas (Source: Dresser-Rand, Painted Post, New York).

The air filter must be of the dry type, preferably cloth or paper, and

usually larger than that used for the lubricated compressor in order to

provide adequate filtering area.

Air that may appear clean often contains large quantities of suspended

solids such as dust, soot, and fine particles of cinder, flyash, and sand.

Concentrations range from .50 grains per 1,000 cu. ft. in rural areas to 5

grains per 1,000 cu. ft. in industrial areas. Because 7,000 grains equals 1

pound, a 1,000 cfm compressor, operating 24 hours per day in an indus-

trial atmosphere will, without filtration, ingest 1.03 pounds of dust per

day. These solid contaminants accelerate abrasion, wear, and erosion.