Page 93 - Reciprocating Compressors Operation Maintenance

P. 93

8O Reciprocating Compressors: Operation and Maintenance

Press

Plunger

Hardwood

Block

Adjustable

Blocks

Teflon

Wearing

Ring

Polished

Hardwood

Mandrel

Piston

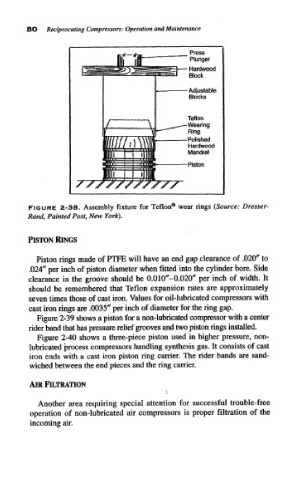

FIGURE 2-38. Assembly fixture for Teflon® wear rings (Source: Dresser-

Rand, Painted Post, New York).

PISTON RINGS

Piston rings made of PTFE will have an end gap clearance of .020" to

.024" per inch of piston diameter when fitted into the cylinder bore. Side

clearance in the groove should be 0.010"-0.020" per inch of width. It

should be remembered that Teflon expansion rates are approximately

seven times those of cast iron. Values for oil-lubricated compressors with

cast iron rings are .0035" per inch of diameter for the ring gap.

Figure 2-39 shows a piston for a non-lubricated compressor with a center

rider band that has pressure relief grooves and two piston rings installed.

Figure 2-40 shows a three-piece piston used in higher pressure, non-

lubricated process compressors handling synthesis gas. It consists of cast

iron ends with a cast iron piston ring carrier. The rider bands are sand-

wiched between the end pieces and the ring carrier.

AIR FILTRATION

j

Another area requiring special attention for successful trouble-free

operation of non-lubricated air compressors is proper filtration of the

incoming air.