Page 294 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 294

262 Refining Biomass Residues for Sustainable Energy and Bioproducts

tops and leaves (trash) during the harvesting procedures. The energy obtained from

the recoverable dry leaf is equivalent to 10 tons of coal per hectare which is of one-

third of energy total energy available. Sugarcane mills possess significant contribu-

tion in the production of exportable energy from the cane trash with the reduced

release of carbon dioxide compared to conventional fossil fuel systems. The energy

produced from sugarcane is significantly higher than the energy obtained from the

coal. The cost of production also cheaper for sugarcane sources when compared to

crude oil/coal with carbon capture. Dry cane trash has the potential to replace the

natural energy deficit by 50%, as it generates high potential energy for cogeneration

process.

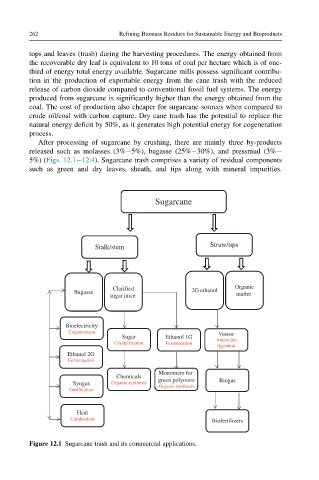

After processing of sugarcane by crushing, there are mainly three by-products

released such as molasses (3% 5%), bagasse (25% 30%), and pressmud (3%

5%) (Figs. 12.1 12.4). Sugarcane trash comprises a variety of residual components

such as green and dry leaves, sheath, and tips along with mineral impurities.

Sugarcane

Stalk/stem Straw/tips

Clarified 2G ethanol Organic

Bagasse matter

sugar juice

Bioelectricity

Cogeneration Vinasse

Sugar Ethanol 1G

Crystallization Fermentation Anaerobic

digestion

Ethanol 2G

Fermentation

Monomers for

Chemicals

Syngas Organic synthesis green polymers Biogas

Gasification Organic synthesis

Heat

Combustion Biofertilizers

Figure 12.1 Sugarcane trash and its commercial applications.