Page 297 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 297

Effective utilization of sugarcane trash for energy production 265

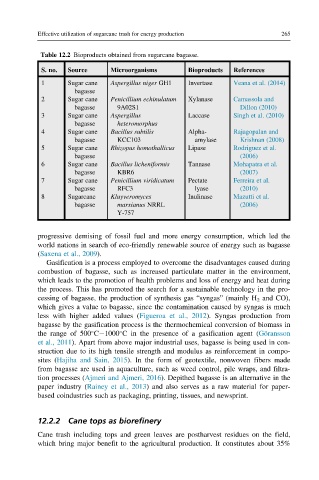

Table 12.2 Bioproducts obtained from sugarcane bagasse.

S. no. Source Microorganisms Bioproducts References

1 Sugar cane Aspergillus niger GH1 Invertase Veana et al. (2014)

bagasse

2 Sugar cane Penicillium echinulatum Xylanase Camassola and

bagasse 9A02S1 Dillon (2010)

3 Sugar cane Aspergillus Laccase Singh et al. (2010)

bagasse heteromorphus

4 Sugar cane Bacillus subtilis Alpha- Rajagopalan and

bagasse KCC103 amylase Krishnan (2008)

5 Sugar cane Rhizopus homothallicus Lipase Rodriguez et al.

bagasse (2006)

6 Sugar cane Bacillus licheniformis Tannase Mohapatra et al.

bagasse KBR6 (2007)

7 Sugar cane Penicillium viridicatum Pectate Ferreira et al.

bagasse RFC3 lyase (2010)

8 Sugarcane Kluyveromyces Inulinase Mazutti et al.

bagasse marxianus NRRL (2006)

Y-757

progressive demising of fossil fuel and more energy consumption, which led the

world nations in search of eco-friendly renewable source of energy such as bagasse

(Saxena et al., 2009).

Gasification is a process employed to overcome the disadvantages caused during

combustion of bagasse, such as increased particulate matter in the environment,

which leads to the promotion of health problems and loss of energy and heat during

the process. This has promoted the search for a sustainable technology in the pro-

cessing of bagasse, the production of synthesis gas “syngas” (mainly H 2 and CO),

which gives a value to bagasse, since the contamination caused by syngas is much

less with higher added values (Figueroa et al., 2012). Syngas production from

bagasse by the gasification process is the thermochemical conversion of biomass in

the range of 500 C 1000 C in the presence of a gasification agent (Go ¨ransson

et al., 2011). Apart from above major industrial uses, bagasse is being used in con-

struction due to its high tensile strength and modulus as reinforcement in compo-

sites (Hajiha and Sain, 2015). In the form of geotextile, nonwoven fibers made

from bagasse are used in aquaculture, such as weed control, pile wraps, and filtra-

tion processes (Ajmeri and Ajmeri, 2016). Depithed bagasse is an alternative in the

paper industry (Rainey et al., 2013) and also serves as a raw material for paper-

based coindustries such as packaging, printing, tissues, and newsprint.

12.2.2 Cane tops as biorefinery

Cane trash including tops and green leaves are postharvest residues on the field,

which bring major benefit to the agricultural production. It constitutes about 35%