Page 36 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 36

Solid waste biorefineries 15

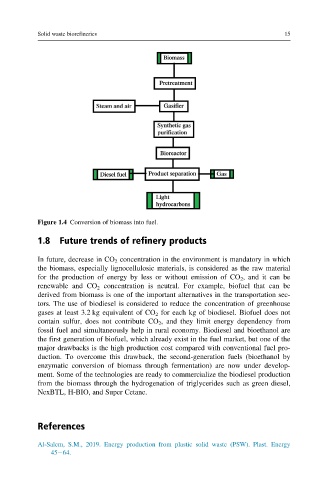

Figure 1.4 Conversion of biomass into fuel.

1.8 Future trends of refinery products

In future, decrease in CO 2 concentration in the environment is mandatory in which

the biomass, especially lignocellulosic materials, is considered as the raw material

for the production of energy by less or without emission of CO 2 , and it can be

renewable and CO 2 concentration is neutral. For example, biofuel that can be

derived from biomass is one of the important alternatives in the transportation sec-

tors. The use of biodiesel is considered to reduce the concentration of greenhouse

gases at least 3.2 kg equivalent of CO 2 for each kg of biodiesel. Biofuel does not

contain sulfur, does not contribute CO 2 , and they limit energy dependency from

fossil fuel and simultaneously help in rural economy. Biodiesel and bioethanol are

the first generation of biofuel, which already exist in the fuel market, but one of the

major drawbacks is the high production cost compared with conventional fuel pro-

duction. To overcome this drawback, the second-generation fuels (bioethanol by

enzymatic conversion of biomass through fermentation) are now under develop-

ment. Some of the technologies are ready to commercialize the biodiesel production

from the biomass through the hydrogenation of triglycerides such as green diesel,

NexBTL, H-BIO, and Super Cetane.

References

Al-Salem, S.M., 2019. Energy production from plastic solid waste (PSW). Plast. Energy

45 64.