Page 413 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 413

Agroindustry wastes: biofuels and biomaterials feedstocks for sustainable rural development 373

Acid forming Methane forming

organisms organisms

Methane

Organic Volatile and

waste acids

carbon dioxide

Phase 1 Phase 2

Acid Methane

fermentation fermentation

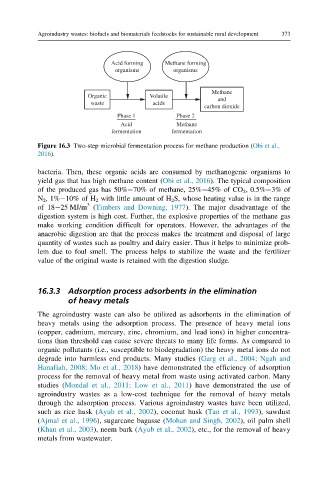

Figure 16.3 Two-step microbial fermentation process for methane production (Obi et al.,

2016).

bacteria. Then, these organic acids are consumed by methanogenic organisms to

yield gas that has high methane content (Obi et al., 2016). The typical composition

of the produced gas has 50% 70% of methane, 25% 45% of CO 2 , 0.5% 3% of

N 2 ,1% 10% of H 2 with little amount of H 2 S, whose heating value is in the range

3

of 18 25 MJ/m (Timbers and Downing, 1977). The major disadvantage of the

digestion system is high cost. Further, the explosive properties of the methane gas

make working condition difficult for operators. However, the advantages of the

anaerobic digestion are that the process makes the treatment and disposal of large

quantity of wastes such as poultry and dairy easier. Thus it helps to minimize prob-

lem due to foul smell. The process helps to stabilize the waste and the fertilizer

value of the original waste is retained with the digestion sludge.

16.3.3 Adsorption process adsorbents in the elimination

of heavy metals

The agroindustry waste can also be utilized as adsorbents in the elimination of

heavy metals using the adsorption process. The presence of heavy metal ions

(copper, cadmium, mercury, zinc, chromium, and lead ions) in higher concentra-

tions than threshold can cause severe threats to many life forms. As compared to

organic pollutants (i.e., susceptible to biodegradation) the heavy metal ions do not

degrade into harmless end products. Many studies (Garg et al., 2004; Ngah and

Hanafiah, 2008; Mo et al., 2018) have demonstrated the efficiency of adsorption

process for the removal of heavy metal from waste using activated carbon. Many

studies (Mondal et al., 2011; Low et al., 2011) have demonstrated the use of

agroindustry wastes as a low-cost technique for the removal of heavy metals

through the adsorption process. Various agroindustry wastes have been utilized,

such as rice husk (Ayub et al., 2002), coconut husk (Tan et al., 1993), sawdust

(Ajmal et al., 1996), sugarcane bagasse (Mohan and Singh, 2002), oil palm shell

(Khan et al., 2003), neem bark (Ayub et al., 2002), etc., for the removal of heavy

metals from wastewater.