Page 67 - Reliability and Maintainability of In service Pipelines

P. 67

56 Reliability and Maintainability of In-Service Pipelines

If the ring deflection (i.e., ΔXtðÞ) exceeds the allowable threshold (0:05D i ),

the ring deflection failure will happen. Ring deflection can be calculated by

Eq. (2.6) (BS 9295, 2010).

ð

KD L W c 1 P s ÞD m

ΔX 5 ð2:6Þ

8EI 0

D 3 1 0:061E

m

The allowable threshold for ring deflection suggested by BS 9295, 2010 is 5%

of inside diameter of the pipe.

Leakage: Leakages reduce the reliability of a pipeline significantly, because a

leak can lead to a rupture if not identified and treated appropriately. Leakage hap-

pens when the depth of corrosion pit exceeds the pipe wall thickness. Leakage

can be considered as a serviceability limit state and the formulation for the limit

state function can be presented as Eq. (2.7).

G Δ; W t ; tð Þ 5 Δ tðÞ 2 W t ð2:7Þ

In which Δ tðÞ is the depth of corrosion and W t is the critical value for leakage

which is the pipe wall thickness.

Buckling: Buckling can be a major form of reliability reduction mostly for

plastic pipelines, due to having more flexible structure in comparison to steel,

concrete, and clay. Buckling affects the reliability of a pipeline due to the stretch-

ing of the pipeline which leads to a thinning in the pipe wall, and consequently

thinner walls reduce the structural reliability.

Buckling as a serviceability limit state is also considered as one of the critical

failure modes which should be kept less than its critical thresholds to guarantee

the safety of pipeline.

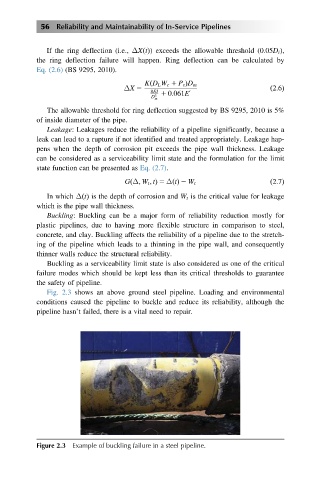

Fig. 2.3 shows an above ground steel pipeline. Loading and environmental

conditions caused the pipeline to buckle and reduce its reliability, although the

pipeline hasn’t failed, there is a vital need to repair.

Figure 2.3 Example of buckling failure in a steel pipeline.