Page 288 - Renewable Energy Devices and System with Simulations in MATLAB and ANSYS

P. 288

Marine and Hydrokinetic Power Generation and Power Plants 275

Induction Turbine Collector

generator transformer bus

G-box

Grid

PFC

capacitors

FIGURE 11.8 Type 1 MHK generator—induction generator. (Courtesy of NREL, Denver, CO.)

Induction Collector

generator bus

G-box

Turbine Grid

transformer

Variable

resistor

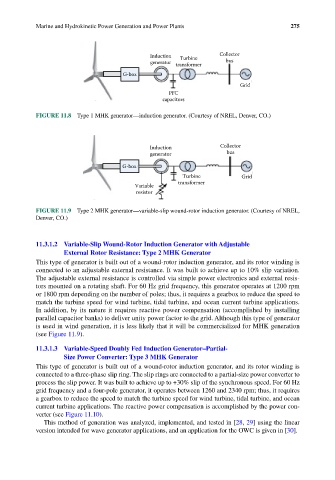

FIGURE 11.9 Type 2 MHK generator—variable-slip wound-rotor induction generator. (Courtesy of NREL,

Denver, CO.)

11.3.1.2 Variable-Slip Wound-Rotor Induction Generator with Adjustable

External Rotor Resistance: Type 2 MHK Generator

This type of generator is built out of a wound-rotor induction generator, and its rotor winding is

connected to an adjustable external resistance. It was built to achieve up to 10% slip variation.

The adjustable external resistance is controlled via simple power electronics and external resis-

tors mounted on a rotating shaft. For 60 Hz grid frequency, this generator operates at 1200 rpm

or 1800 rpm depending on the number of poles; thus, it requires a gearbox to reduce the speed to

match the turbine speed for wind turbine, tidal turbine, and ocean current turbine applications.

In addition, by its nature it requires reactive power compensation (accomplished by installing

parallel capacitor banks) to deliver unity power factor to the grid. Although this type of generator

is used in wind generation, it is less likely that it will be commercialized for MHK generation

(see Figure 11.9).

11.3.1.3 Variable-Speed Doubly Fed Induction Generator–Partial-

Size Power Converter: Type 3 MHK Generator

This type of generator is built out of a wound-rotor induction generator, and its rotor winding is

connected to a three-phase slip ring. The slip rings are connected to a partial-size power converter to

process the slip power. It was built to achieve up to +30% slip of the synchronous speed. For 60 Hz

grid frequency and a four-pole generator, it operates between 1260 and 2340 rpm; thus, it requires

a gearbox to reduce the speed to match the turbine speed for wind turbine, tidal turbine, and ocean

current turbine applications. The reactive power compensation is accomplished by the power con-

verter (see Figure 11.10).

This method of generation was analyzed, implemented, and tested in [28, 29] using the linear

version intended for wave generator applications, and an application for the OWC is given in [30].