Page 133 - Robot Builder's Bonanza

P. 133

102 BUILD A MOTORIZED PLASTIC PLATFORM

Cutouts for

wheels

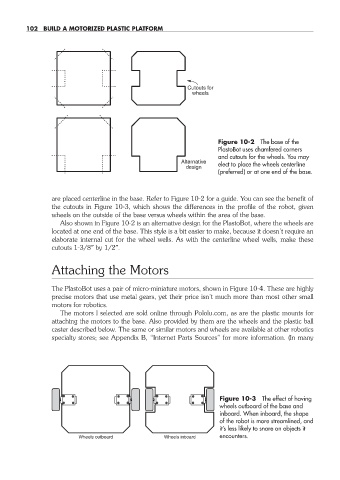

Figure 10-2 The base of the

PlastoBot uses chamfered corners

and cutouts for the wheels. You may

Alternative

design elect to place the wheels centerline

(preferred) or at one end of the base.

are placed centerline in the base. Refer to Figure 10-2 for a guide. You can see the benefit of

the cutouts in Figure 10-3, which shows the differences in the profile of the robot, given

wheels on the outside of the base versus wheels within the area of the base.

Also shown in Figure 10-2 is an alternative design for the PlastoBot, where the wheels are

located at one end of the base. This style is a bit easier to make, because it doesn’t require an

elaborate internal cut for the wheel wells. As with the centerline wheel wells, make these

cutouts 1-3/8″ by 1/2″.

Attaching the Motors

The PlastoBot uses a pair of micro- miniature motors, shown in Figure 10-4. These are highly

precise motors that use metal gears, yet their price isn’t much more than most other small

motors for robotics.

The motors I selected are sold online through Pololu.com, as are the plastic mounts for

attaching the motors to the base. Also provided by them are the wheels and the plastic ball

caster described below. The same or similar motors and wheels are available at other robotics

specialty stores; see Appendix B, “Internet Parts Sources” for more information. (In many

Figure 10-3 The effect of having

wheels outboard of the base and

inboard. When inboard, the shape

of the robot is more streamlined, and

it’s less likely to snare on objects it

Wheels outboard Wheels inboard encounters.

10-chapter-10.indd 102 4/21/11 11:45 AM