Page 260 - Robot Builder's Bonanza

P. 260

AVOIDING ELECTRICAL NOISE 229

Additional capacitors

soldered to terminal

and motor case

Motor

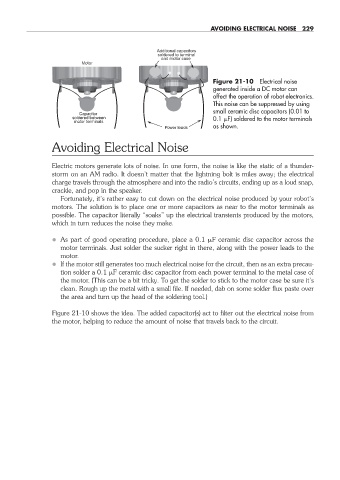

Figure 21- 10 Electrical noise

generated inside a DC motor can

affect the operation of robot electronics.

This noise can be suppressed by using

small ceramic disc capacitors (0.01 to

Capacitor

soldered between 0.1 F) soldered to the motor terminals

motor terminals

Power leads as shown.

Avoiding Electrical Noise

Electric motors generate lots of noise. In one form, the noise is like the static of a thunder-

storm on an AM radio. It doesn’t matter that the lightning bolt is miles away; the electrical

charge travels through the atmosphere and into the radio’s circuits, ending up as a loud snap,

crackle, and pop in the speaker.

Fortunately, it’s rather easy to cut down on the electrical noise produced by your robot’s

motors. The solution is to place one or more capacitors as near to the motor terminals as

possible. The capacitor literally “soaks” up the electrical transients produced by the motors,

which in turn reduces the noise they make.

• As part of good operating procedure, place a 0.1 F ceramic disc capacitor across the

motor terminals. Just solder the sucker right in there, along with the power leads to the

motor.

• If the motor still generates too much electrical noise for the circuit, then as an extra precau-

tion solder a 0.1 F ceramic disc capacitor from each power terminal to the metal case of

the motor. (This can be a bit tricky. To get the solder to stick to the motor case be sure it’s

clean. Rough up the metal with a small file. If needed, dab on some solder flux paste over

the area and turn up the head of the soldering tool.)

Figure 21- 10 shows the idea. The added capacitor(s) act to filter out the electrical noise from

the motor, helping to reduce the amount of noise that travels back to the circuit.

21-chapter-21.indd 229 4/21/11 11:50 AM