Page 323 - Robot Builder's Bonanza

P. 323

292 ROBOT MOVEMENT WITH SHAPE MEMORY ALLOY

Pulley

Deactuate Actuate

SMA wire

Lever

Spring SMA wire

Bias spring

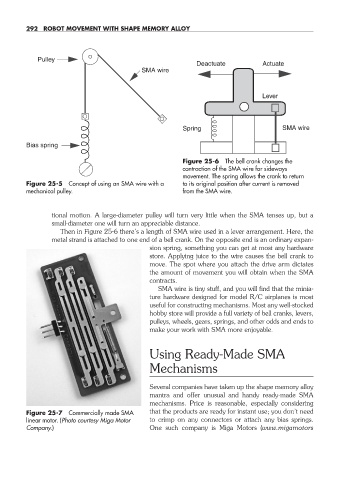

Figure 25- 6 The bell crank changes the

contraction of the SMA wire for sideways

movement. The spring allows the crank to return

Figure 25- 5 Concept of using an SMA wire with a to its original position after current is removed

mechanical pulley. from the SMA wire.

tional motion. A large- diameter pulley will turn very little when the SMA tenses up, but a

small- diameter one will turn an appreciable distance.

Then in Figure 25- 6 there’s a length of SMA wire used in a lever arrangement. Here, the

metal strand is attached to one end of a bell crank. On the opposite end is an ordinary expan-

sion spring, something you can get at most any hardware

store. Applying juice to the wire causes the bell crank to

move. The spot where you attach the drive arm dictates

the amount of movement you will obtain when the SMA

contracts.

SMA wire is tiny stuff, and you will find that the minia-

ture hardware designed for model R/C airplanes is most

useful for constructing mechanisms. Most any well- stocked

hobby store will provide a full variety of bell cranks, levers,

pulleys, wheels, gears, springs, and other odds and ends to

make your work with SMA more enjoyable.

Using Ready- Made SMA

Mechanisms

Several companies have taken up the shape memory alloy

mantra and offer unusual and handy ready- made SMA

mechanisms. Price is reasonable, especially considering

Figure 25- 7 Commercially made SMA that the products are ready for instant use; you don’t need

linear motor. (Photo courtesy Miga Motor to crimp on any connectors or attach any bias springs.

Company.) One such company is Miga Motors (www.migamotors

25-chapter-25.indd 292 4/21/11 11:51 AM