Page 211 - Robotics Designing the Mechanisms for Automated Machinery

P. 211

5.3 Force Sensors 199

This sensor consists of magnetic circuit 1, coil 2, and membrane 3 made of ferromag-

netic material and influenced by the measured pressure. The initial air gap between 3

and 2 is about 0.2-0.5 mm.

Figure 5.37 shows a capacitance sensor consisting of membrane 1, made as one

piece with the housing, and an immobile electrode 2 insulated from the housing by

bushing 3. The air gap between 1 and 2 must be as small as possible. The accuracy of

these devices is about 2%.

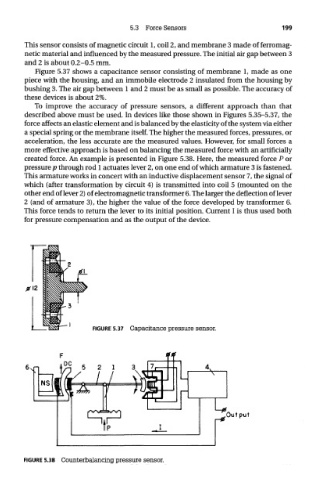

To improve the accuracy of pressure sensors, a different approach than that

described above must be used. In devices like those shown in Figures 5.35-5.37, the

force affects an elastic element and is balanced by the elasticity of the system via either

a special spring or the membrane itself. The higher the measured forces, pressures, or

acceleration, the less accurate are the measured values. However, for small forces a

more effective approach is based on balancing the measured force with an artificially

created force. An example is presented in Figure 5.38. Here, the measured force P or

pressure p through rod 1 actuates lever 2, on one end of which armature 3 is fastened.

This armature works in concert with an inductive displacement sensor 7, the signal of

which (after transformation by circuit 4) is transmitted into coil 5 (mounted on the

other end of lever 2) of electromagnetic transformer 6. The larger the deflection of lever

2 (and of armature 3), the higher the value of the force developed by transformer 6.

This force tends to return the lever to its initial position. Current I is thus used both

for pressure compensation and as the output of the device.

FIGURE 5.37 Capacitance pressure sensor.

FIGURE 5.38 Counterbalancing pressure sensor.