Page 207 - Robotics Designing the Mechanisms for Automated Machinery

P. 207

5.3 Force Sensors 195

The devices described so far transform the acceleration into force, and the latter is

in some way transformed into an electrical signal. All these devices involve contact with

the item being measured. A noncontact method for acceleration measurement during

vibrations is based on the Doppler effect that appears when a laser beam reflects from

the vibrating surface. This method is suitable for research measurements under labo-

ratory conditions rather than for use in industrial automatic machines and robots, and

will not be described here. The method is an effective but still very expensive means.

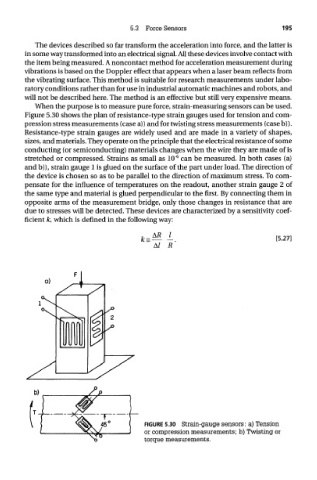

When the purpose is to measure pure force, strain-measuring sensors can be used.

Figure 5.30 shows the plan of resistance-type strain gauges used for tension and com-

pression stress measurements (case a)) and for twisting stress measurements (case b)).

Resistance-type strain gauges are widely used and are made in a variety of shapes,

sizes, and materials. They operate on the principle that the electrical resistance of some

conducting (or semiconducting) materials changes when the wire they are made of is

6

stretched or compressed. Strains as small as 10" can be measured. In both cases (a)

and b)), strain gauge 1 is glued on the surface of the part under load. The direction of

the device is chosen so as to be parallel to the direction of maximum stress. To com-

pensate for the influence of temperatures on the readout, another strain gauge 2 of

the same type and material is glued perpendicular to the first. By connecting them in

opposite arms of the measurement bridge, only those changes in resistance that are

due to stresses will be detected. These devices are characterized by a sensitivity coef-

ficient k, which is defined in the following way:

FIGURE 5.30 Strain-gauge sensors: a) Tension

or compression measurements; b) Twisting or

torciue measurements.