Page 204 - Robotics Designing the Mechanisms for Automated Machinery

P. 204

192 Feedback Sensors

rate. These devices are suitable for a wide range of flow rates, from very small to thou-

sands of cubic meters per hour. The accuracy is 1-2%.

To increase the sensitivity of the device and make it suitable for rapidly changing flow

rates, the thermoresistors must have very small masses to reduce their thermal inertia.

Figure 5.25 schematically shows such a thermoresistor. On a base 1, in the form of a

truncated cone made of a material with low heat conductivity, a thin (1-mm) film 2 of

platinum (or other metal) is applied. The other dimensions of this film are about 0.2 by

1 mm. The film is provided with leads 3. The plane of the film is oriented according to

the flow's speed vector. Such sensors can respond to fast flow changes of up to 100 kHz.

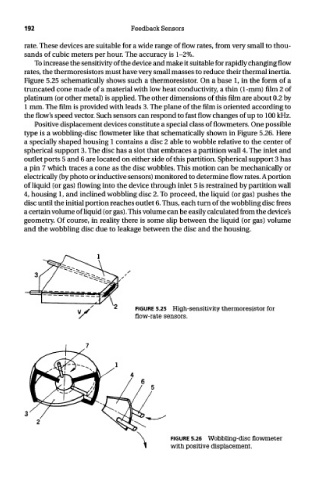

Positive displacement devices constitute a special class of flowmeters. One possible

type is a wobbling-disc flowmeter like that schematically shown in Figure 5.26. Here

a specially shaped housing 1 contains a disc 2 able to wobble relative to the center of

spherical support 3. The disc has a slot that embraces a partition wall 4. The inlet and

outlet ports 5 and 6 are located on either side of this partition. Spherical support 3 has

a pin 7 which traces a cone as the disc wobbles. This motion can be mechanically or

electrically (by photo or inductive sensors) monitored to determine flow rates. A portion

of liquid (or gas) flowing into the device through inlet 5 is restrained by partition wall

4, housing 1, and inclined wobbling disc 2. To proceed, the liquid (or gas) pushes the

disc until the initial portion reaches outlet 6. Thus, each turn of the wobbling disc frees

a certain volume of liquid (or gas). This volume can be easily calculated from the device's

geometry. Of course, in reality there is some slip between the liquid (or gas) volume

and the wobbling disc due to leakage between the disc and the housing.

FIGURE 5.25 High-sensitivity thermoresistor for

flow-rate sensors.

FIGURE 5.26 Wobbling-disc flowmeter

with positive displacement.