Page 215 - Robotics Designing the Mechanisms for Automated Machinery

P. 215

5.5 Item Presence Sensors 203

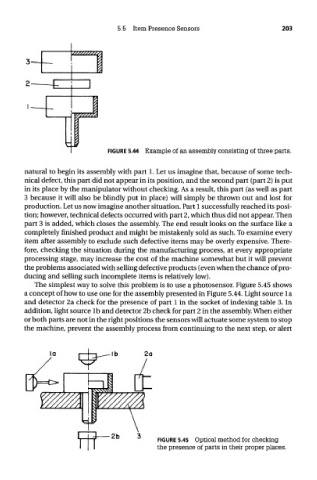

FIGURE 5.44 Example of an assembly consisting of three parts.

natural to begin its assembly with part 1. Let us imagine that, because of some tech-

nical defect, this part did not appear in its position, and the second part (part 2) is put

in its place by the manipulator without checking. As a result, this part (as well as part

3 because it will also be blindly put in place) will simply be thrown out and lost for

production. Let us now imagine another situation. Part 1 successfully reached its posi-

tion; however, technical defects occurred with part 2, which thus did not appear. Then

part 3 is added, which closes the assembly The end result looks on the surface like a

completely finished product and might be mistakenly sold as such. To examine every

item after assembly to exclude such defective items may be overly expensive. There-

fore, checking the situation during the manufacturing process, at every appropriate

processing stage, may increase the cost of the machine somewhat but it will prevent

the problems associated with selling defective products (even when the chance of pro-

ducing and selling such incomplete items is relatively low).

The simplest way to solve this problem is to use a photosensor. Figure 5.45 shows

a concept of how to use one for the assembly presented in Figure 5.44. Light source la

and detector 2a check for the presence of part 1 in the socket of indexing table 3. In

addition, light source Ib and detector 2b check for part 2 in the assembly. When either

or both parts are not in the right positions the sensors will actuate some system to stop

the machine, prevent the assembly process from continuing to the next step, or alert

FIGURE 5.45 Optical method for checking

the presence of parts in their proper places.