Page 219 - Robotics Designing the Mechanisms for Automated Machinery

P. 219

6.2 Linear Transportation 207

• Maintaining constant tension (in the paper, fabric, wire, threads, etc., that are

handled);

• Maintaining constant speed of the running material;

• Handling the problem of stretching of some materials during their processing

(thermal treatment, humidity and drying, plastic deformation, etc.);

• Maintaining a constant rate of consumption of the transported material. (This

is close to, although not exactly the same as, keeping the speed constant.)

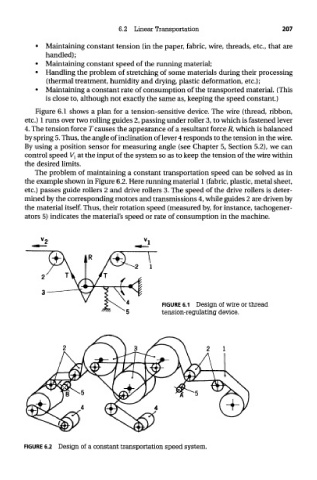

Figure 6.1 shows a plan for a tension-sensitive device. The wire (thread, ribbon,

etc.) 1 runs over two rolling guides 2, passing under roller 3, to which is fastened lever

4. The tension force T causes the appearance of a resultant force R, which is balanced

by spring 5. Thus, the angle of inclination of lever 4 responds to the tension in the wire.

By using a position sensor for measuring angle (see Chapter 5, Section 5.2), we can

control speed V 1 at the input of the system so as to keep the tension of the wire within

the desired limits.

The problem of maintaining a constant transportation speed can be solved as in

the example shown in Figure 6.2. Here running material 1 (fabric, plastic, metal sheet,

etc.) passes guide rollers 2 and drive rollers 3. The speed of the drive rollers is deter-

mined by the corresponding motors and transmissions 4, while guides 2 are driven by

the material itself. Thus, their rotation speed (measured by, for instance, tachogener-

ators 5) indicates the material's speed or rate of consumption in the machine.

FIGURE 6.1 Design of wire or thread

tension-regulating device.

FIGURE 6.2 Design of a constant transportation speed system.