Page 234 - Robotics Designing the Mechanisms for Automated Machinery

P. 234

222 Transporting Devices

This mechanism must be equivalent to that shown in Figure 6. 19, which means that

rotation angle 0 5 of lever 5 and rotation angle 0 4 of wheel 4 (or the rotation angle of

arm 1) are related by some definite ratio. It is easy to understand that, between any

two positions, 0 5 = 144° = (2/5)360°. With regard to angle 0 4, attention must be paid to

the fact that the length of arc III-IV (as well as those of arcs I-II, II-III, and IV-V; dashed

lines in Figure 6.19) equals the circumference of wheel 4. From this fact it follows that

angle 0 4 may be expressed as

The consequence of this statement is

Thus, Expression (6.8) can be rewritten as

The other condition we must provide is the radius R. This is made by choosing the

proper dimensions for planet gear 7.

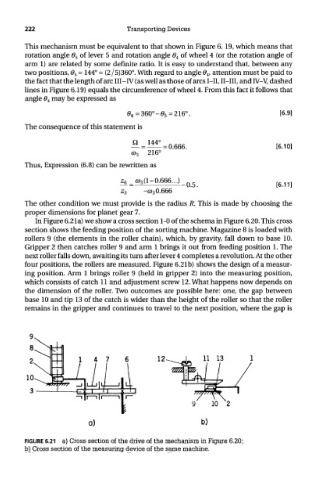

In Figure 6.21a) we show a cross section 1-0 of the schema in Figure 6.20. This cross

section shows the feeding position of the sorting machine. Magazine 8 is loaded with

rollers 9 (the elements in the roller chain), which, by gravity, fall down to base 10.

Gripper 2 then catches roller 9 and arm 1 brings it out from feeding position 1. The

next roller falls down, awaiting its turn after lever 4 completes a revolution. At the other

four positions, the rollers are measured. Figure 6.21b) shows the design of a measur-

ing position. Arm 1 brings roller 9 (held in gripper 2) into the measuring position,

which consists of catch 11 and adjustment screw 12. What happens now depends on

the dimension of the roller. Two outcomes are possible here: one, the gap between

base 10 and tip 13 of the catch is wider than the height of the roller so that the roller

remains in the gripper and continues to travel to the next position, where the gap is

FIGURE 6.21 a) Cross section of the drive of the mechanism in Figure 6.20;

b) Cross section of the measuring device of the same machine.