Page 303 - Robots Androids and Animatrons : 12 Incredible Projects You Can Build

P. 303

The most widely used industrial robot is the robotic arm. Robotic

arms are extremely versatile, due to the fact that the end manip-

ulator of a robotic arm can be changed to fit particular tasks or

industries. For instance, welding gear manipulators are used in

spot-welding robots, spray nozzles for spray painting parts and

assemblies, and grippers for pick and place, to name a few.

So you see, robotic arms are useful and make for an ideal learning

tool. However, building a robotic arm from scratch is a difficult

task. It is far easier to assemble a robotic arm from a kit. OWI sells

a suitable robotic arm kit available from a number of electronic

distributors (see the parts listing at the end of the chapter). The

interface connects the finished robotic arm kit to a host computer

printer port. The host computer is any IBM PC or compatible com-

puter capable of running DOS or Windows 95/98.

Once connected to the computer’s printer port, the robotic arm

may be operated interactively and programmed from the com-

puter. Operating the robotic arm interactively is easy. Simply click

on any function button to command the robotic arm to perform that

function. Click on the button a second time to end the function.

Programming automation is just as easy. First click on the Program

282 button to enter the program mode. In this mode, the interface and

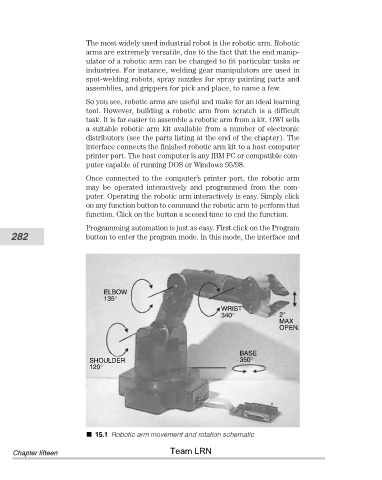

ELBOW

135°

WRIST

340° 2"

MAX

OPEN.

BASE

SHOULDER 350°

120°

15.1 Robotic arm movement and rotation schematic

Team LRN

Chapter fifteen