Page 119 - Rock Mechanics For Underground Mining

P. 119

BEHAVIOUR OF ISOTROPIC ROCK MATERIAL IN MULTIAXIAL COMPRESSION

c was only 15%. For 2 = 1 , no strength increase was observed (i.e. 1 = c ).

The practical consequence of these results is that, for this rock type, the ‘strength-

ening’ effect of the intermediate principal stress can be neglected so that the uniax-

ial compressive strength, c , should be used as the rock material strength whenever

3 = 0. This slightly conservative conclusion is likely to apply to a wide range of rock

types.

4.4.3 Triaxial compression ( 1 > 2 = 3 )

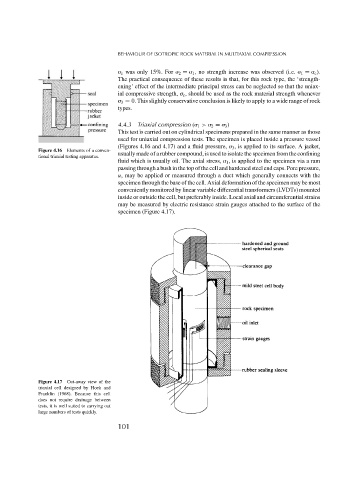

This test is carried out on cylindrical specimens prepared in the same manner as those

used for uniaxial compression tests. The specimen is placed inside a pressure vessel

(Figures 4.16 and 4.17) and a fluid pressure, 3 , is applied to its surface. A jacket,

Figure 4.16 Elements of a conven-

tional triaxial testing apparatus. usually made of a rubber compound, is used to isolate the specimen from the confining

fluid which is usually oil. The axial stress, 1 , is applied to the specimen via a ram

passing through a bush in the top of the cell and hardened steel end caps. Pore pressure,

u, may be applied or measured through a duct which generally connects with the

specimen through the base of the cell. Axial deformation of the specimen may be most

conveniently monitored by linear variable differential transformers (LVDTs) mounted

inside or outside the cell, but preferably inside. Local axial and circumferential strains

may be measured by electric resistance strain gauges attached to the surface of the

specimen (Figure 4.17).

Figure 4.17 Cut-away view of the

triaxial cell designed by Hoek and

Franklin (1968). Because this cell

does not require drainage between

tests, it is well suited to carrying out

large numbers of tests quickly.

101