Page 230 - Rock Mechanics For Underground Mining

P. 230

EXCAVATION DESIGN IN MASSIVE ELASTIC ROCK

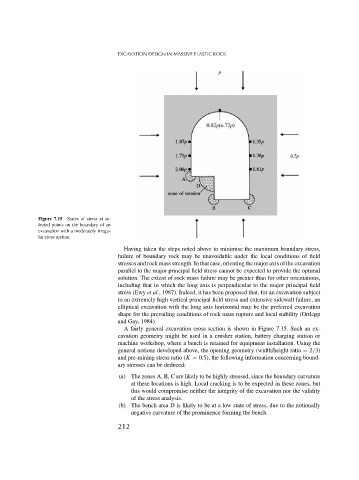

Figure 7.15 States of stress at se-

lected points on the boundary of an

excavation with a moderately irregu-

lar cross section.

Having taken the steps noted above to minimise the maximum boundary stress,

failure of boundary rock may be unavoidable under the local conditions of field

stresses and rock mass strength. In that case, orienting the major axis of the excavation

parallel to the major principal field stress cannot be expected to provide the optimal

solution. The extent of rock mass failure may be greater than for other orientations,

including that in which the long axis is perpendicular to the major principal field

stress (Ewy et al., 1987). Indeed, it has been proposed that, for an excavation subject

to an extremely high vertical principal field stress and extensive sidewall failure, an

elliptical excavation with the long axis horizontal may be the preferred excavation

shape for the prevailing conditions of rock mass rupture and local stability (Ortlepp

and Gay, 1984).

A fairly general excavation cross section is shown in Figure 7.15. Such an ex-

cavation geometry might be used in a crusher station, battery charging station or

machine workshop, where a bench is retained for equipment installation. Using the

general notions developed above, the opening geometry (width/height ratio = 2/3)

and pre-mining stress ratio (K = 0.5), the following information concerning bound-

ary stresses can be deduced:

(a) The zones A, B, C are likely to be highly stressed, since the boundary curvature

at these locations is high. Local cracking is to be expected in these zones, but

this would compromise neither the integrity of the excavation nor the validity

of the stress analysis.

(b) The bench area D is likely to be at a low state of stress, due to the notionally

negative curvature of the prominence forming the bench.

212