Page 376 - Rock Mechanics For Underground Mining

P. 376

MINING METHODS AND METHOD SELECTION

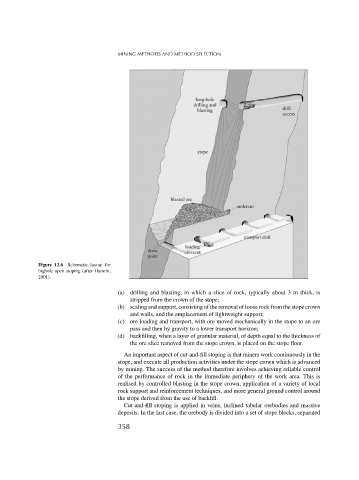

Figure 12.6 Schematic layout for

bighole open stoping (after Hamrin,

2001).

(a) drilling and blasting, in which a slice of rock, typically about 3 m thick, is

stripped from the crown of the stope;

(b) scaling and support, consisting of the removal of loose rock from the stope crown

and walls, and the emplacement of lightweight support;

(c) ore loading and transport, with ore moved mechanically in the stope to an ore

pass and then by gravity to a lower transport horizon;

(d) backfilling, when a layer of granular material, of depth equal to the thickness of

the ore slice removed from the stope crown, is placed on the stope floor.

An important aspect of cut-and-fill stoping is that miners work continuously in the

stope, and execute all production activities under the stope crown which is advanced

by mining. The success of the method therefore involves achieving reliable control

of the performance of rock in the immediate periphery of the work area. This is

realised by controlled blasting in the stope crown, application of a variety of local

rock support and reinforcement techniques, and more general ground control around

the stope derived from the use of backfill.

Cut-and-fill stoping is applied in veins, inclined tabular orebodies and massive

deposits. In the last case, the orebody is divided into a set of stope blocks, separated

358