Page 378 - Rock Mechanics For Underground Mining

P. 378

MINING METHODS AND METHOD SELECTION

the method, for the mine external environment, include limited possibility of mining-

induced surface subsidence. Reduction in surface storage of mined wastes follows

from possible replacement of a high proportion of these materials in the stoping ex-

cavations. De-slimed mill tailings are particularly suitable for backfilling, since the

material may be readily transported hydraulically to working areas. This eliminates

the need for extra mine development for transfer of backfill underground.

The amount of stope development for cut-and-fill stoping is small, compared with

open stoping. The reasons for this are that the production source is also the working

site, and some access openings may be developed as stoping progresses. On the other

hand, stope block pre-production development may be comparable with that required

for open stoping. Cut-and-fill stoping can commence only after developing a transport

level, ore passes, sill incline and sill drift, service and access raises or inclines, and

return air raises.

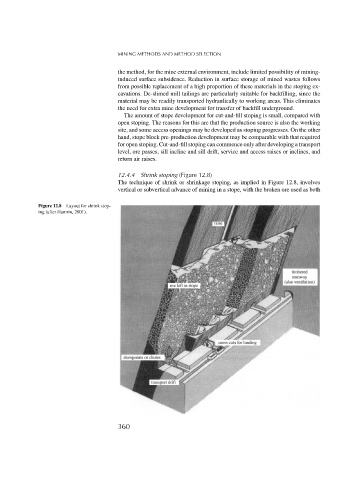

12.4.4 Shrink stoping (Figure 12.8)

The technique of shrink or shrinkage stoping, as implied in Figure 12.8, involves

vertical or subvertical advance of mining in a stope, with the broken ore used as both

Figure 12.8 Layout for shrink stop-

ing (after Hamrin, 2001).

360