Page 382 - Rock Mechanics For Underground Mining

P. 382

MINING METHODS AND METHOD SELECTION

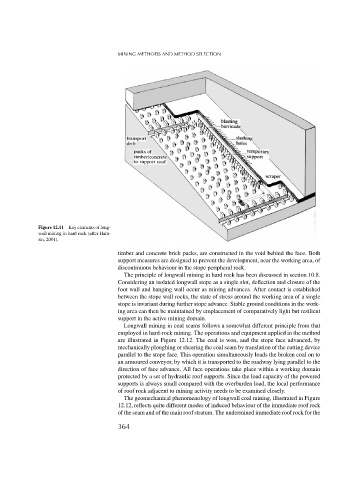

Figure 12.11 Key elements of long-

wall mining in hard rock (after Ham-

rin, 2001).

timber and concrete brick packs, are constructed in the void behind the face. Both

support measures are designed to prevent the development, near the working area, of

discontinuous behaviour in the stope peripheral rock.

The principle of longwall mining in hard rock has been discussed in section 10.8.

Considering an isolated longwall stope as a single slot, deflection and closure of the

foot wall and hanging wall occur as mining advances. After contact is established

between the stope wall rocks, the state of stress around the working area of a single

stope is invariant during further stope advance. Stable ground conditions in the work-

ing area can then be maintained by emplacement of comparatively light but resilient

support in the active mining domain.

Longwall mining in coal seams follows a somewhat different principle from that

employed in hard-rock mining. The operations and equipment applied in the method

are illustrated in Figure 12.12. The coal is won, and the stope face advanced, by

mechanically ploughing or shearing the coal seam by translation of the cutting device

parallel to the stope face. This operation simultaneously loads the broken coal on to

an armoured conveyor, by which it is transported to the roadway lying parallel to the

direction of face advance. All face operations take place within a working domain

protected by a set of hydraulic roof supports. Since the load capacity of the powered

supports is always small compared with the overburden load, the local performance

of roof rock adjacent to mining activity needs to be examined closely.

The geomechanical phenomenology of longwall coal mining, illustrated in Figure

12.12, reflects quite different modes of induced behaviour of the immediate roof rock

of the seam and of the main roof stratum. The undermined immediate roof rock for the

364