Page 415 - Rock Mechanics For Underground Mining

P. 415

STOPE-AND-PILLAR DESIGN IN IRREGULAR OREBODIES

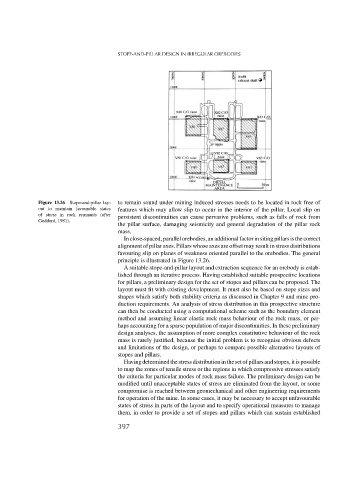

Figure 13.26 Stope-and-pillar lay- to remain sound under mining induced stresses needs to be located in rock free of

out to maintain favourable states features which may allow slip to occur in the interior of the pillar. Local slip on

of stress in rock remnants (after persistent discontinuities can cause pervasive problems, such as falls of rock from

Goddard, 1981).

the pillar surface, damaging seismicity and general degradation of the pillar rock

mass.

In close-spaced, parallel orebodies, an additional factor in siting pillars is the correct

alignment of pillar axes. Pillars whose axes are offset may result in stress distributions

favouring slip on planes of weakness oriented parallel to the orebodies. The general

principle is illustrated in Figure 13.26.

A suitable stope-and-pillar layout and extraction sequence for an orebody is estab-

lished through an iterative process. Having established suitable prospective locations

for pillars, a preliminary design for the set of stopes and pillars can be proposed. The

layout must fit with existing development. It must also be based on stope sizes and

shapes which satisfy both stability criteria as discussed in Chapter 9 and mine pro-

duction requirements. An analysis of stress distribution in this prospective structure

can then be conducted using a computational scheme such as the boundary element

method and assuming linear elastic rock mass behaviour of the rock mass, or per-

haps accounting for a sparse population of major discontinuities. In these preliminary

design analyses, the assumption of more complex constitutive behaviour of the rock

mass is rarely justified, because the initial problem is to recognise obvious defects

and limitations of the design, or perhaps to compare possible alternative layouts of

stopes and pillars.

Havingdeterminedthestressdistributioninthesetofpillarsandstopes,itispossible

to map the zones of tensile stress or the regions in which compressive stresses satisfy

the criteria for particular modes of rock mass failure. The preliminary design can be

modified until unacceptable states of stress are eliminated from the layout, or some

compromise is reached between geomechanical and other engineering requirements

for operation of the mine. In some cases, it may be necessary to accept unfavourable

states of stress in parts of the layout and to specify operational measures to manage

them, in order to provide a set of stopes and pillars which can sustain established

397