Page 84 - Rock Mechanics For Underground Mining

P. 84

ROCK MASS STRUCTURE AND CHARACTERISATION

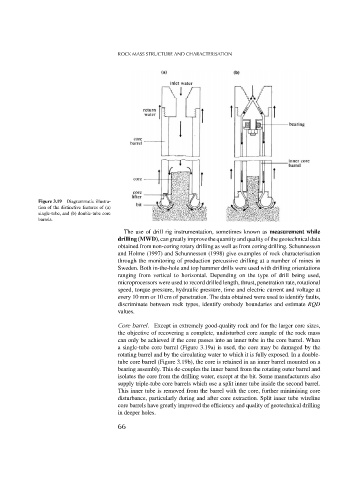

Figure 3.19 Diagrammatic illustra-

tion of the distinctive features of (a)

single-tube, and (b) double-tube core

barrels.

The use of drill rig instrumentation, sometimes known as measurement while

drilling (MWD), can greatly improve the quantity and quality of the geotechnical data

obtained from non-coring rotary drilling as well as from coring drilling. Schunnesson

and Holme (1997) and Schunnesson (1998) give examples of rock characterisation

through the monitoring of production percussive drilling at a number of mines in

Sweden. Both in-the-hole and top hammer drills were used with drilling orientations

ranging from vertical to horizontal. Depending on the type of drill being used,

microprocessors were used to record drilled length, thrust, penetration rate, rotational

speed, torque pressure, hydraulic pressure, time and electric current and voltage at

every 10 mm or 10 cm of penetration. The data obtained were used to identify faults,

discriminate between rock types, identify orebody boundaries and estimate RQD

values.

Core barrel. Except in extremely good-quality rock and for the larger core sizes,

the objective of recovering a complete, undisturbed core sample of the rock mass

can only be achieved if the core passes into an inner tube in the core barrel. When

a single-tube core barrel (Figure 3.19a) is used, the core may be damaged by the

rotating barrel and by the circulating water to which it is fully exposed. In a double-

tube core barrel (Figure 3.19b), the core is retained in an inner barrel mounted on a

bearing assembly. This de-couples the inner barrel from the rotating outer barrel and

isolates the core from the drilling water, except at the bit. Some manufacturers also

supply triple-tube core barrels which use a split inner tube inside the second barrel.

This inner tube is removed from the barrel with the core, further minimising core

disturbance, particularly during and after core extraction. Split inner tube wireline

core barrels have greatly improved the efficiency and quality of geotechnical drilling

in deeper holes.

66