Page 104 - Root Cause Failure Analysis

P. 104

Pumps 95

suction inlet on one side and a discharge outlet on the other. A cylindrical-shaped

rotor having a diameter smaller than the cylinder is driven about an axis position

above the cylinder’s centerline. The clearance between the rotor and the top of the cyl-

inder is small, but it increases toward the bottom.

The rotor has vanes that move in and out as it rotates, maintaining a sealed space

between the rotor and the cylinder wall. The vanes trap liquid on the suction side and

carry it to the discharge side, where contraction of the space expels it through the dis-

charge line. The vanes may swing on pivots or slide in slots in the rotor.

Lobe

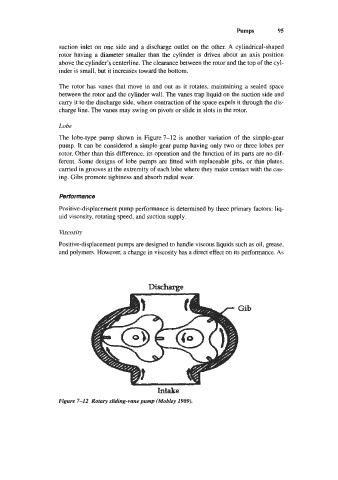

The lobe-type pump shown in Figure 7-12 is another variation of the simple-gear

pump. It can be considered a simple-gear pump having only two or three lobes per

rotor. Other than this difference, its operation and the function of its parts are no dif-

ferent. Some designs of lobe pumps are fitted with replaceable gibs, or thin plates,

carried in grooves at the extremity of each lobe where they make contact with the cas-

ing. Gibs promote tightness and absorb radial wear.

performance

Positive-displacement pump performance is determined by three primary factors: liq-

uid viscosity, rotating speed, and suction supply.

ViscosiQ

Positive-displacement pumps are designed to handle viscous liquids such as oil, grease,

and polymers. However, a change in viscosity has a direct effect on its performance. As

Intake

Figure 7-12 Rotary sliding-vane pump (Mobley 1989).