Page 101 - Root Cause Failure Analysis

P. 101

92 Root Cause Failure Analysis

Configuration

Positive-displacement pumps come in a variety of configurations. Each has a specific

function and should be selected based on the effectiveness and reliability in a specific

application. The major types of positive-displacement pumps are gear, screw, vane,

and lobe.

Gear

The most common type of positive-displacement pump uses a combination of gears

and configurations to provide the liquid pressure and volume required by the applica-

tion. Variations of gear pumps are spur, helical, and herringbone.

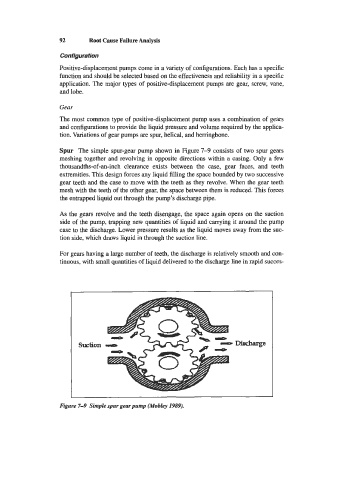

Spur The simple spur-gear pump shown in Figure 7-9 consists of two spur gears

meshing together and revolving in opposite directions within a casing. Only a few

thousandths-of-an-inch clearance exists between the case, gear faces, and teeth

extremities. This design forces any liquid filling the space bounded by two successive

gear teeth and the case to move with the teeth as they revolve. When the gear teeth

mesh with the teeth of the other gear, the space between them is reduced. This forces

the entrapped liquid out through the pump’s discharge pipe.

As the gears revolve and the teeth disengage, the space again opens on the suction

side of the pump, trapping new quantities of liquid and carrying it around the pump

case to the discharge. Lower pressure results as the liquid moves away from the suc-

tion side, which draws liquid in through the suction line.

For gears having a large number of teeth, the discharge is relatively smooth and con-

tinuous, with small quantities of liquid delivered to the discharge line in rapid succes-

Strction

I

Figure 7-9 Simple spur gear pump (Mobky 1989).