Page 132 - Root Cause Failure Analysis

P. 132

120 Root Cause Failure Aniysis

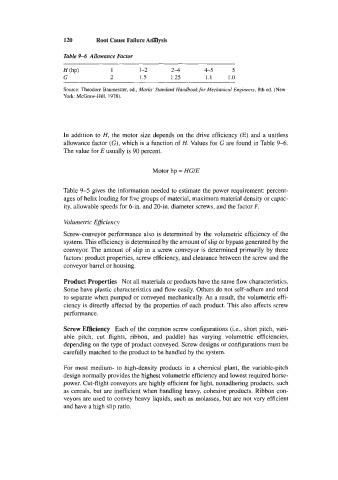

Table 9-6 Allowance Factor

H (he) I 1-2 2-4 4-5 5

G 2 1.5 1.25 1.1 1 .o

Source: Theodore Baumeister, ed., Marh' Standard Handbook for Mechanical Engineers, 8th ed. (New

York: McGraw-Hill, 1978).

In addition to H, the motor size depends on the drive efficiency (E) and a unitless

allowance factor (G), which is a function of H. Values for G are found in Table 9-6.

The value for E usually is 90 percent.

Motor hp = HGIE

Table 9-5 gives the information needed to estimate the power requirement: percent-

ages of helix loading for five groups of material, maximum material density or capac-

ity, allowable speeds for 6-in. and 20-in. diameter screws, and the factor F.

Volumetric Eficiency

Screw-conveyor performance also is determined by the volumetric efficiency of the

system. This efficiency is determined by the amount of slip or bypass generated by the

conveyor. The amount of slip in a screw conveyor is determined primarily by three

factors: product properties, screw efficiency, and clearance between the screw and the

conveyor barrel or housing.

Product Properties Not all materials or products have the same flow characteristics.

Some have plastic characteristics and flow easily. Others do not self-adhere and tend

to separate when pumped or conveyed mechanically. As a result, the volumetric effi-

ciency is directly affected by the properties of each product. This also affects screw

performance.

Screw Efficiency Each of the common screw configurations (Le., short pitch, vari-

able pitch, cut flights, ribbon, and paddle) has varying volumetric efficiencies,

depending on the type of product conveyed. Screw designs or configurations must be

carefully matched to the product to be handled by the system.

For most medium- to high-density products in a chemical plant, the variable-pitch

design normally provides the highest volumetric efficiency and lowest required horse-

power. Cut-flight conveyors are highly efficient for light, nonadhering products, such

as cereals, but are inefficient when handling heavy, cohesive products. Ribbon con-

veyors are used to convey heavy liquids, such as molasses, but are not very efficient

and have a high slip ratio.