Page 137 - Root Cause Failure Analysis

P. 137

Compressors 125

The impeller configuration has a major impact on stability and the operating enve-

lope. There are two impeller configurations: in-line and back-to-back, or opposed.

With the in-line design, all impellers face in the same direction. With the opposed

design, impeller direction is reversed in adjacent stages.

In-Line A compressor with all impellers facing in the same direction generates sub-

stantial axial forces. The axial pressures generated by each impeller for all the stages

are additive. As a result, massive axial loads are transmitted to the fixed bearing.

Because of this load, most of these compressors use either a Kingsbury thrust bearing

or a balancing piston to resist axial thrusting. Figure 10-3 illustrates a typical balanc-

ing piston.

All compressors that use in-line impellers must be monitored closely for axial thrust-

ing. If the compressor is subjected to frequent or constant unloading, the axial clear-

ance will increase due to this thrusting cycle. Ultimately, this frequent thrust loading

will lead to catastrophic failure of the compressor.

Opposed By reversing the direction of alternating impellers, the axial forces gener-

ated by each impeller or stage can be minimized. In effect, the opposed impellers tend

to cancel the axial forces generated by the preceding stage. This design is more stable

and should not generate measurable axial thrusting, which allows these units to con-

tain a normal float and fixed rolling-element bearing.

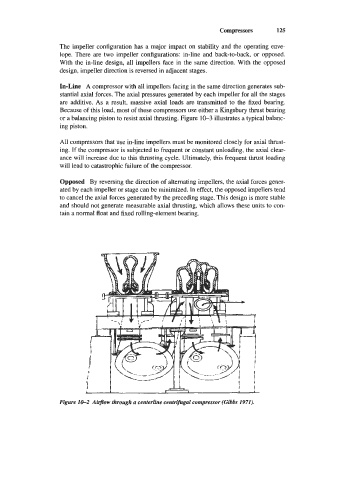

Figure 10-2 AirJlow through a centerline centrifugal compressor (Gibbs 1971).