Page 154 - Root Cause Failure Analysis

P. 154

142 Root Cause Failure Analysis

ClWlkSMt

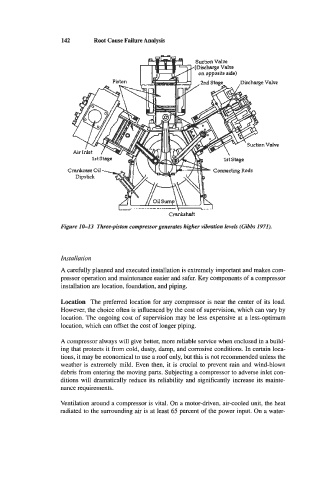

Figure 10-13 Three-piston compressor generates higher vibration levels (Gibbs 1971).

installation

A carefully planned and executed installation is extremely important and makes com-

pressor operation and maintenance easier and safer. Key components of a compressor

installation are location, foundation, and piping.

Location The preferred location for any compressor is near the center of its load.

However, the choice often is influenced by the cost of supervision, which can vary by

location. The ongoing cost of supervision may be less expensive at a less-optimum

location, which can offset the cost of longer piping.

A compressor always will give better, more reliable service when enclosed in a build-

ing that protects it from cold, dusty, damp, and corrosive conditions. In certain loca-

tions, it may be economical to use a roof only, but this is not recommended unless the

weather is extremely mild. Even then, it is crucial to prevent rain and wind-blown

debris from entering the moving parts. Subjecting a compressor to adverse inlet con-

ditions will dramatically reduce its reliability and significantly increase its mainte-

nance requirements.

Ventilation around a compressor is vital. On a motor-driven, air-cooled unit, the heat

radiated to the surrounding air is at least 65 percent of the power input. On a water-