Page 238 - Root Cause Failure Analysis

P. 238

226 Root Cause Failure Analysis

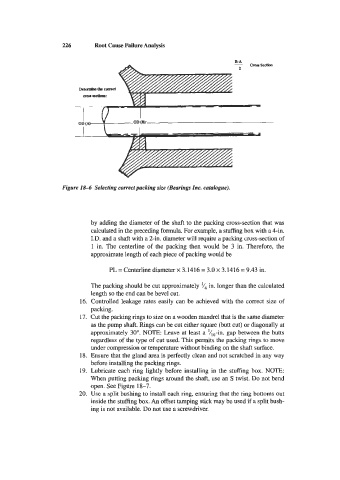

Figure 18-6 Selecting correct packing size (Bearings Znc. catalogue).

by adding the diameter of the shaft to the packing cross-section that was

calculated in the preceding formula. For example, a stuffing box with a 4-in.

I.D. and a shaft with a 2-in. diameter will require a packing cross-section of

1 in. The centerline of the packing then would be 3 in. Therefore, the

approximate length of each piece of packing would be

PL = Centerline diameter x 3.1416 = 3.0 x 3.1416 = 9.43 in.

The packing should be cut approximately v4 in. longer than the calculated

length so the end can be bevel cut.

16. Controlled leakage rates easily can be achieved with the correct size of

packing.

17. Cut the packing rings to size on a wooden mandrel that is the same diameter

as the pump shaft. Rings can be cut either square (butt cut) or diagonally at

approximately 30". NOTE Leave at least a g6-in. gap between the butts

regardless of the type of cut used. This permits the packing rings to move

under compression or temperature without binding on the shaft surface.

18. Ensure that the gland area is perfectly clean and not scratched in any way

before installing the packing rings.

19. Lubricate each ring lightly before installing in the stuffing box. NOTE:

When putting packing rings around the shaft, use an S twist. Do not bend

open. See Figure 18-7.

20. Use a split bushing to install each ring, ensuring that the ring bottoms out

inside the stuffing box. An offset tamping stick may be used if a split bush-

ing is not available. Do not use a screwdriver.