Page 119 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 119

Misalignment of Machine Shafts

Force from

Magnetic Force Driven Equipment

➔

➔

Motor Rotor Operating

Out of Its Magnetic Center

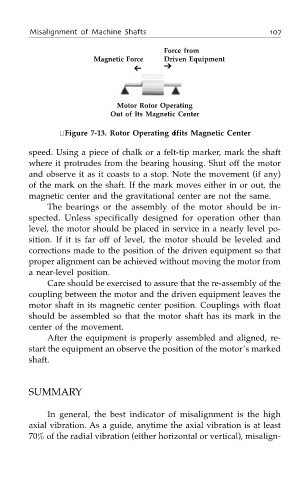

Figure 7-13. Rotor Operating off its Magnetic Center

speed. Using a piece of chalk or a felt-tip marker, mark the shaft

where it protrudes from the bearing housing. Shut off the motor

and observe it as it coasts to a stop. Note the movement (if any)

of the mark on the shaft. If the mark moves either in or out, the

magnetic center and the gravitational center are not the same.

The bearings or the assembly of the motor should be in-

spected. Unless specifically designed for operation other than

level, the motor should be placed in service in a nearly level po-

sition. If it is far off of level, the motor should be leveled and

corrections made to the position of the driven equipment so that

proper alignment can be achieved without moving the motor from

a near-level position.

Care should be exercised to assure that the re-assembly of the

coupling between the motor and the driven equipment leaves the

motor shaft in its magnetic center position. Couplings with float

should be assembled so that the motor shaft has its mark in the

center of the movement.

After the equipment is properly assembled and aligned, re-

start the equipment an observe the position of the motor’s marked

shaft.

SUMMARY

In general, the best indicator of misalignment is the high

axial vibration. As a guide, anytime the axial vibration is at least

70% of the radial vibration (either horizontal or vertical), misalign-