Page 125 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 125

Advanced Machine Alignment

gap under the foot.

Re-torque the hold-down bolt and move to the next one.

Draw a simple sketch of the machine, and record the movement

or gap for each foot. All feet should exhibit about the same move-

ment or gap. If the difference is more than 2 mils, add the proper

amount of shims under the feet with the excessive movement, so

that all are the same. Once this has been completed, the work on

the stationary machine is completed, except for some checks for

potential sources of unbalance. This procedure should now be

performed on the adjustable machine. See the appendix section for

additional details.

Regardless of the alignment method to be employed, it is

highly recommended that the vertical alignment be corrected first.

This will allow the machine to be moved horizontally without

disturbing the vertical alignment. If the horizontal alignment were

corrected first, moving the machine in the vertical plane would

most likely disrupt the horizontal alignment.

.005”

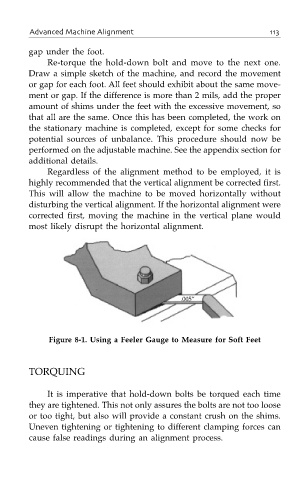

Figure 8-1. Using a Feeler Gauge to Measure for Soft Feet

TORQUING

It is imperative that hold-down bolts be torqued each time

they are tightened. This not only assures the bolts are not too loose

or too tight, but also will provide a constant crush on the shims.

Uneven tightening or tightening to different clamping forces can

cause false readings during an alignment process.