Page 129 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 129

Advanced Machine Alignment

can cause major problems. Large and obvious defects are usually

corrected when they are detected. However, the smaller seemingly

insignificant things are too often ignored.

THE ALIGNMENT FIXTURE AND BAR SAG

One of the first steps in any alignment process is to deter-

mine how to set up a fixture that will allow you to take the re-

quired measurements. In aligning two shafts, the readings are

taken from the stationary shaft to the adjustable shaft, across the

coupling. Always mount the fixture to read from the STATION-

ARY equipment to the ADJUSTABLE equipment!

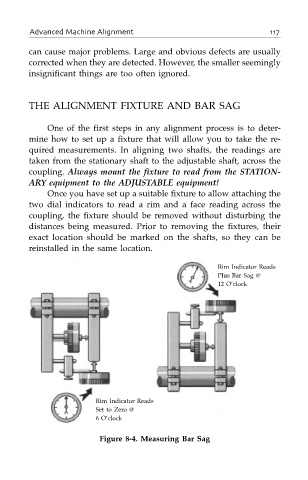

Once you have set up a suitable fixture to allow attaching the

two dial indicators to read a rim and a face reading across the

coupling, the fixture should be removed without disturbing the

distances being measured. Prior to removing the fixtures, their

exact location should be marked on the shafts, so they can be

reinstalled in the same location.

Rim Indicator Reads

Plus Bar Sag @

12 O’clock

Rim Indicator Reads

Set to Zero @

6 O’clock

Figure 8-4. Measuring Bar Sag