Page 133 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 133

Advanced Machine Alignment

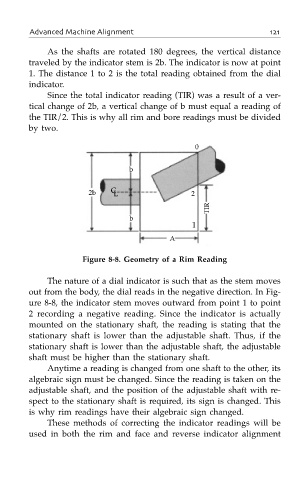

As the shafts are rotated 180 degrees, the vertical distance

traveled by the indicator stem is 2b. The indicator is now at point

1. The distance 1 to 2 is the total reading obtained from the dial

indicator.

Since the total indicator reading (TIR) was a result of a ver-

tical change of 2b, a vertical change of b must equal a reading of

the TIR/2. This is why all rim and bore readings must be divided

by two.

0

b

2b C L 2

TIR

b

1

A

Figure 8-8. Geometry of a Rim Reading

The nature of a dial indicator is such that as the stem moves

out from the body, the dial reads in the negative direction. In Fig-

ure 8-8, the indicator stem moves outward from point 1 to point

2 recording a negative reading. Since the indicator is actually

mounted on the stationary shaft, the reading is stating that the

stationary shaft is lower than the adjustable shaft. Thus, if the

stationary shaft is lower than the adjustable shaft, the adjustable

shaft must be higher than the stationary shaft.

Anytime a reading is changed from one shaft to the other, its

algebraic sign must be changed. Since the reading is taken on the

adjustable shaft, and the position of the adjustable shaft with re-

spect to the stationary shaft is required, its sign is changed. This

is why rim readings have their algebraic sign changed.

These methods of correcting the indicator readings will be

used in both the rim and face and reverse indicator alignment