Page 131 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 131

Advanced Machine Alignment

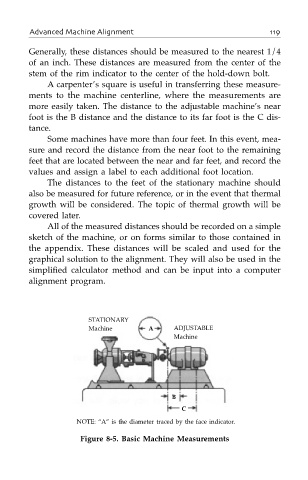

Generally, these distances should be measured to the nearest 1/4

of an inch. These distances are measured from the center of the

stem of the rim indicator to the center of the hold-down bolt.

A carpenter’s square is useful in transferring these measure-

ments to the machine centerline, where the measurements are

more easily taken. The distance to the adjustable machine’s near

foot is the B distance and the distance to its far foot is the C dis-

tance.

Some machines have more than four feet. In this event, mea-

sure and record the distance from the near foot to the remaining

feet that are located between the near and far feet, and record the

values and assign a label to each additional foot location.

The distances to the feet of the stationary machine should

also be measured for future reference, or in the event that thermal

growth will be considered. The topic of thermal growth will be

covered later.

All of the measured distances should be recorded on a simple

sketch of the machine, or on forms similar to those contained in

the appendix. These distances will be scaled and used for the

graphical solution to the alignment. They will also be used in the

simplified calculator method and can be input into a computer

alignment program.

STATIONARY

Machine A ADJUSTABLE

Machine

B

C

NOTE: “A” is the diameter traced by the face indicator.

Figure 8-5. Basic Machine Measurements